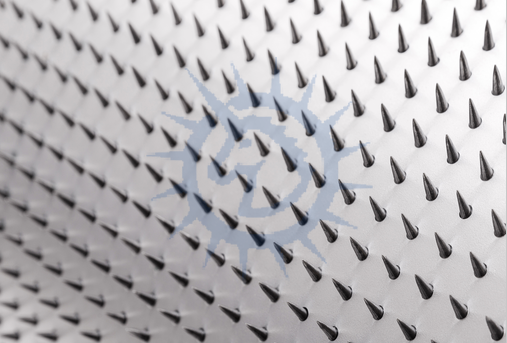

STEWARTS Pins are drawn from high grade carbon steel, hardened and tempered an en polished. The grain of the metal and the machining marks of the pin all run along its axis, so fibres can float freely around the point, and there are no snags to catch fibres or start wear.

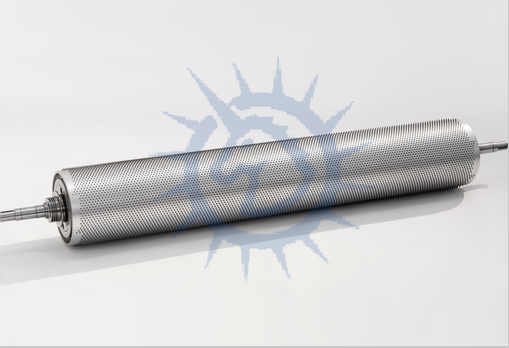

The working lifetime of a STEWARTS pinned roller is astonishing to those used to regularly replacing card-wire,and it is common to find STEWARTS Rollers still running reliably after many years.

Pins are "Fibre Friendly"

The smooth, rounded shape of a pin does much less damage to delicate fibre than conventional card-wire. The sharp point of a Pin also gives excellent fibre penetration. The result is exceptional fibre opening with minimum fibre damage. Consequently staple length is maintained.

STEWARTS have over l25years'experience in solving the World's fibre processing problems.

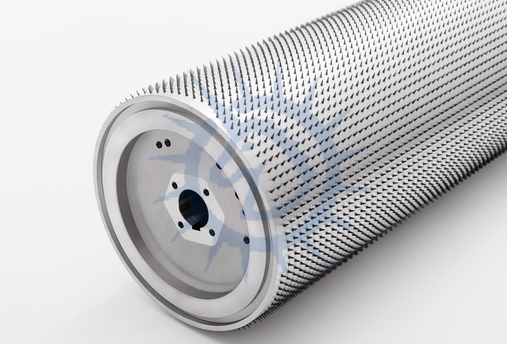

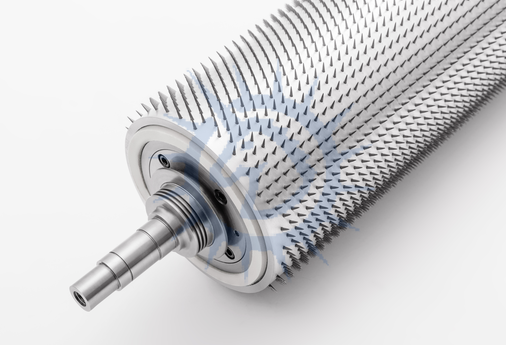

Integral Construction, Advanced Design

The STEWARTS family of Blowroom Rollers is an integrated range of products, alldesigned to take full advantage of the qualities of aluminium alloy extrusion and long life carbon steel pins. The rollers are designed and manufactured to a very high engineering standarc and are dynamically balanced before despatch.

STEWARTS Rollers are ideal for fitting as Original Equipment or as a simple and cost effective way to upgrade existing machinery.

We have designs for most current machines, whether solid-type, multi-lag or three-lag, and can also provide replacement lags and other components for conversions. This range of designs also offers control over air-flow, which is essential for good cleaning.

Cleaning Cotton

Cotton bales are typically delivered with highly fragmented particles of dirt trapped by and struck to the fibres. As this foreign matter can only be removed from the fibre surfaces, repeated new surfaces must be exposed to continue the cleaning process. The STEWARTS family of pinned rollers clearly fulfils this role, and it is now generally believed that the first opener and cleaner of a blowroom line should be a pinned roller.

Subsequent Carding

Material processed over pinned blowroom rollers is thoroughly opened and therefore in an ideal state for subsequent carding.

Upgrading Existing Machinery

STEWARTS rollers and lags are designed to be easily fitted to existing machinery, thus providing a very cost effective way to increase efficiency. A wide range of options for conversion can be offered, ranging from individual lags to complete roller assemblies.

Resistance to Damage

Each pin is separately fixed so any accidental damage is restricted and there is no risk of further damage caused by wire stripping.

The STEWARTS "quick change system" means that all or individual lags can be rapidly and easily replaced while the roller is still in the machine. This simplifies maintenance and reduces expensive downtime.