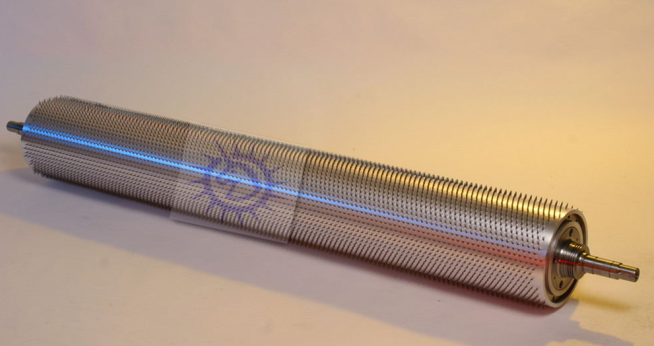

Many processing tools are needed in the textile and garment industry, for example, an auxiliary tool for punching is called a needle roller. The needle roller is a device that is installed on the punching machine to punch various processed fabrics, so it can be used once and for all. Now all walks of life are pursuing automated production, and the emergence of needle rollers satisfies the automation needs of textile and apparel fabrics. However, it is inevitable that the needle roller will deform during use. So what is the reason for this phenomenon? Let's let the needle roller manufacturer explain it to you.

(1) The quality of the drill bit of the needle roller after heating is not good enough, and the increase in temperature causes its deformation to increase, and then when drilling, the needle roller will be damaged and deformed due to uneven force at the punching place. In the actual processing process, since most of the punching machines are relatively precise, the needle rollers that are not of good quality are more likely to deform.

(2) The accuracy of the punching machine is relatively poor, and it is difficult to meet the actual needs of use. When the punching machine is punching, the machine shakes and causes the punching process to be sorry, the needle roller is easy to be biased, and then the needle roller cannot enter the hole during the punching process, and the drill bit deforms.

(3) The precision of the steel needle of the needle roller is relatively poor. Many of the precision controls are not in place during processing. In some places, there is no way to punch in according to the established hole when punching. As the number of uses increases, It will cause deformation of its steel needles.

By understanding the reasons for the deformation of the needle roller, I believe you will pay more attention to the process of buying and using the needle roller in the future. Nowadays, textile and garment processing is mass production, so the loss of machinery and equipment in the actual processing process is also relatively common.